Continuous Induction Sealing Machine

Price 85000.00 INR/ Number

Continuous Induction Sealing Machine Specification

- Driven Type

- Electric

- Condition

- New

- Automation Grade

- Semi-Automatic

- Color

- White

- Application

- Makes the container airtight; enhances product shelf life

- Type

- Continuous Induction Sealing Machine

- Sealing Type

- Induction Sealing

- Seals Type

- Airtight Seal

- Packaging Material

- Plastic Other Airtight Container Materials

About Continuous Induction Sealing Machine

Continuous Induction Sealing Machine is suitable for the customers who Carrying out continuous capping operation for small output. The seal is strong, flexible & yet easy to remove and provides protection against contamination. It is manufactured under the supervision of our team of deft professionals, in compliance with industry defined standards. It is highly acclaimed for its compact built, easy maintenance and rugged design. Our esteemed clients can avail this Continuous Induction Sealing Machine from us at leading market prices.

| Capacity |

|

| Model Name/Number |

|

| Voltage |

|

| Material |

|

| Power |

|

| Brand |

|

| Packaging Material |

|

| Usage/Application |

|

| Type |

|

Efficient Airtight Sealing for Enhanced Shelf Life

The Continuous Induction Sealing Machine ensures an effective airtight seal on containers, safeguarding contents from external contaminants. Utilizing induction sealing technology, it not only prevents leakage but also significantly improves product longevity. The semi-automatic operation allows for user-friendly handling and consistent results, making it a perfect choice for businesses focusing on product integrity.

Semi-Automatic Operation for Versatile Applications

Designed with semi-automatic functionality, this machine simplifies the sealing process while maintaining high productivity. The electric drive and new condition guarantee minimal maintenance and reliable performance. Suitable for packaging pharmaceutical, food, cosmetic, and chemical products, this sealing solution adapts seamlessly to diverse industries across India.

FAQs of Continuous Induction Sealing Machine:

Q: How does the Continuous Induction Sealing Machine create an airtight seal?

A: The machine uses induction sealing technology, which generates electromagnetic currents to heat a metallic foil placed on the container mouth. This heat welds the foil to the container, forming a secure, airtight seal that protects the product inside.Q: What types of containers and packaging materials can be sealed with this machine?

A: It is designed to seal plastic containers and other airtight container materials. The machine is versatile, making it suitable for use with a range of packaging materials typically used for food, beverages, pharmaceuticals, and industrial products.Q: When should I use induction sealing for my products?

A: Induction sealing is best applied when you need to protect products from moisture, tampering, and contamination, or when extending shelf life is critical. It is recommended during the final stage of packaging before the products are distributed or stored.Q: Where can exporters, manufacturers, and suppliers in India use this sealing machine?

A: This machine can be integrated into production lines in manufacturing units, warehouses, and packaging facilities across India. Its semi-automatic operation allows it to blend seamlessly into various scales of operation.Q: What is the process involved in operating the semi-automatic induction sealing machine?

A: Place the filled container with the foil-lined cap under the machines sealing head. Activate the machine, which then uses electromagnetic induction to heat the foil, bonding it to the container and creating an airtight seal. The process is quick, efficient, and requires minimal manual intervention.Q: How does using this machine benefit my business?

A: By providing strong, reliable seals, this machine ensures product safety, reduces spoilage, and complies with quality standards. It enhances consumer trust, improves shelf life, and can lead to cost savings from reduced product wastage.Q: Can the machine handle batch processing for medium-scale operations?

A: Yes, the semi-automatic design is well-suited for medium-scale batch processing, offering consistent sealing performance while allowing manual placement of containers without extensive automation infrastructure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Induction Sealing Machine Category

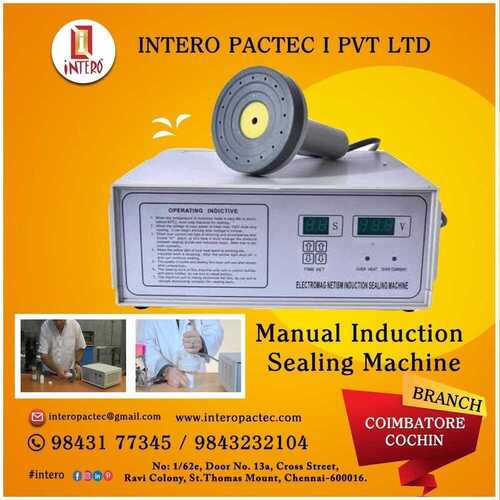

Manual Induction Sealing Machine

Price 14500 INR / Number

Minimum Order Quantity : 1 Number

Weight : 4 Kilograms (kg)

Power : SINGLE PHASE Volt (v)

Automation Grade : MANUAL

Color : GRAY

Manual Induction Sealing Machine In Pollachi

Price 14500 INR / Number

Minimum Order Quantity : 1 Number

Weight : 4 kg (approx.)

Power : 500 W

Automation Grade : Manual

Color : White/Blue

Manual Induction Sealing Machine

Price 14500 INR / Number

Minimum Order Quantity : 1 , , Number

Weight : 4.5 Kg

Power : 500 W

Automation Grade : Manual

Color : White

Bottle Cap Sealing Machine

Price 11500 INR / Number

Minimum Order Quantity : 1 Number

Weight : 5 Kilograms (kg)

Power : 220/50HZ Volt (v)

|

INTERO PACTEC INDIA PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry